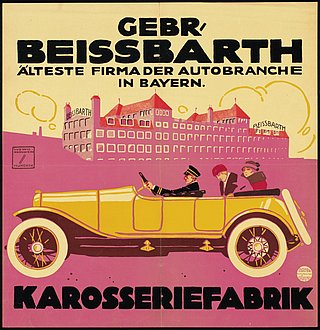

1899

The Beginning of a Movement

In Munich, twin brothers Daniel and Hermann Beissbarth founded Bavaria’s first automobile factory: “Gebrüder Beissbarth.” In the same year, they received the world’s first car license plate – “No. 1” – a symbol of the pioneering spirit that continues to define Beissbarth today.

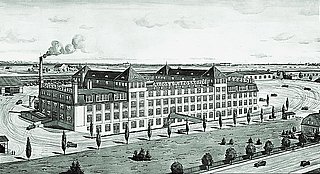

1913

Growth with Vision

With the construction of a four-story factory on Tegernseer Landstraße, Beissbarth made a strong statement: 2,000 m² per floor, a 2,500 m² hall, and a large outdoor area provided space for visionary developments.

1930s–1940s

From Bodywork to Service Equipment

In the 1930s, Beissbarth produced high-quality vehicle bodies for brands such as Daimler and Horch. In the late 1940s, Daniel Beissbarth’s sons, Osmond and Hermann, refocused the company with a clear goal: shaping the future of automotive workshop equipment.

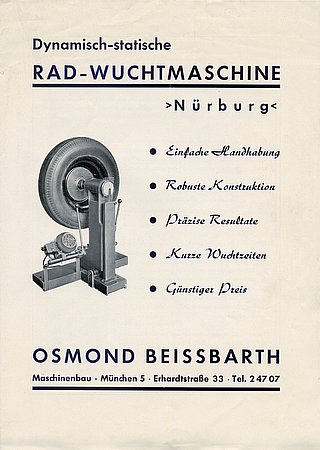

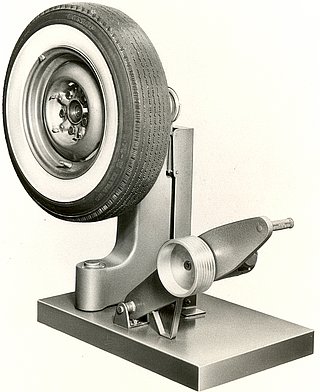

1951

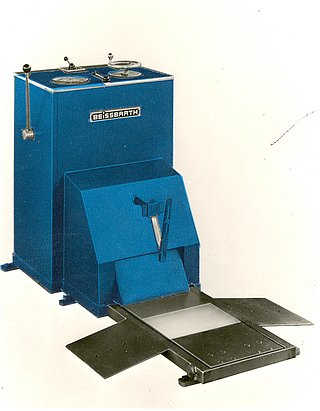

First Passenger Car Wheel Balancer: Model Nürburg

In the 1950s, Beissbarth laid the foundation for modern workshop equipment: the first in-house passenger car wheel balancer, “Model Nürburg,” marked the beginning of an era of technological innovations that would shape workshops worldwide.

1953–1956

Always One Step Ahead

With the first wheel balancer for cars and buses (Model 00), it became possible to balance tire sizes from 8.25 to 20” with a single machine. Beissbarth also introduced the world’s first tire changer, M1, in 1955, revolutionizing tire service. In 1956, the suspension tester S2 became another technical highlight, quickly becoming standard in many workshops, enabling suspension testing and noise measurement directly on the vehicle.

1960

New Facility on Hanauer Straße

Production had reached its limits, and a larger site became necessary. In 1960, a spacious new facility with nearly 4,000 m² of production space was built on Hanauer Straße. The move to the new production site took place on November 18. The product range already included wheel balancers, tire changers, optical aligners, and suspension testers. A milestone was the passenger car tire changer “M8,” introduced in 1959 and sold over 50,000 units by 1982.

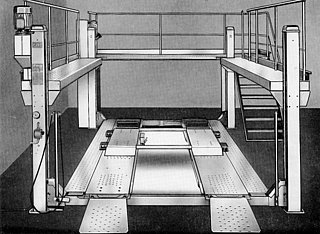

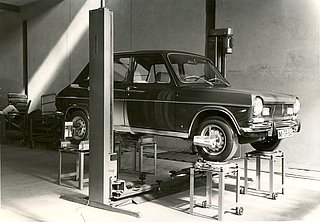

1960

Rethinking Workshop Workflows

A huge sales boost came with entry into the lift business in 1960. The Beissbarth Overhead Testing Stand: a 4-post lift with stairs and grates that allowed work on two levels.

1965

Electronics Arrive

The “W24” became the world’s first electronic wheel balancer, displaying weight size and correction position digitally. In the same year, Beissbarth also developed the optical wheel aligner P5, which at that time measured each axle individually using a projector and a scale.

1972

Founding of the ASA Association and the Birth of Automechanika

As a founding member, Beissbarth helped establish the ASA Association, representing manufacturers and importers of automotive service equipment. The same year marked the first Automechanika, which would later become the world’s leading trade fair for workshop equipment.

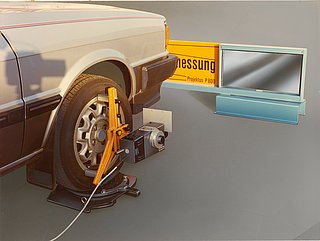

1972

Start of Optical Wheel Alignment

At the first Automechanika, Beissbarth introduced the optical passenger car wheel aligner P800. It became one of the best-selling products of its time and remained in use for almost 20 years. At that time, wheel alignments were still performed on a 2-post lift. For modern suspensions, this method has long been outdated. True precision begins on a dedicated alignment lift.

1979

World First E1200: First CCD Wheel Alignment System with Geometric Driving Axis

The E1200 fundamentally changed wheel alignment. Instead of two projectors, it used four electronic sensor heads attached to the wheels, transmitting data digitally to a monitor. For the first time, the geometric driving axis served as an accurate reference, allowing all measurements to be displayed at the push of a button. This principle still underpins every alignment today.

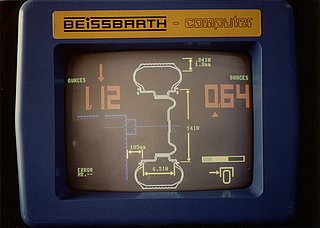

1985

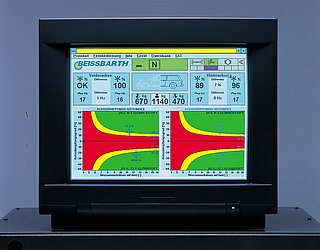

E2200: First Alignment System with Color Monitor

Beissbarth launched an improved system that made alignment more efficient. Twenty-four measurement values could be accessed via remote control on a swivel-mounted color monitor, improving both ergonomics and precision in workshops.

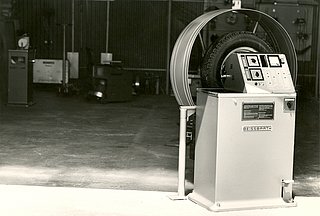

1986

Advances in Wheel Balancing

Beissbarth introduced the computer-controlled W455 wheel balancer with a swivel color display showing imbalance size directly, plus a printout of results. The machine featured an adjustable wheel guard for easier handling, setting new standards in ergonomics, precision, and usability.

1987

Balancing Directly on the Vehicle

The “microtec 600” finish balancer combined microprocessor-controlled measurements with wireless infrared transmission to a portable LCD display, a development later awarded the “Federal Prize for Innovative Achievements.”

1989

Microtec 540: First Wheel Balancer with Runout Measurement and Match Program

The Microtec 540 measured rim runout and included a match program for tire-rim combinations, optimizing overall wheel balance by allowing tire rotation on the rim.

1990s

The High-Tech Era Begins

The Microline 4000 processor-controlled alignment system marked a new era. Monitors, floppy and CD-ROM drives entered workshops, enabling digital measurement and documentation. Combining computer technology, CCD sensors, an 8-channel encoder system, and infrared data transmission, Beissbarth set new benchmarks for precision and efficiency.

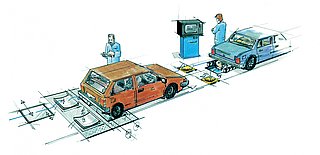

1992

The Test Lane of the Future

A new compact vehicle inspection concept was introduced, based on the Microbrake (MB) 6000 roller brake tester, expandable with a suspension and side slip tester to a full test lane just 1.90 m long. Initially analog, measurements were later displayed on a PC color monitor. In 1994, the system was expanded for trucks and buses with the Microbrake (MB) 8000.

1998

Two World Firsts at the Tire Fair

Beissbarth introduced the Micro Tyre Tester (MTT), an opto-electronic system that uncovers invisible internal tyre damage. The system used laser illumination, a CCD camera and processor-based assessment of the sidewall, split into 8 to 14 segments. Each segment is scanned first at normal air pressure, then under reduced pressure to reveal deformations that indicate interior damage. In about two minutes internal faults and results appear on a monitor. Although experimental, the system showed early on where tyre diagnostics were heading.

The MTT comes in two versions: the MTT 2020 (later RDS8) as a stationary unit with the wheel clamped pneumatically, and the MTT 2100 which integrates into a brake tester so the wheel remains on the vehicle.

In the same year the chassis tester Microsat (MS) 6600 made headlines by revolutionising suspension testing. For the first time measurements could be taken directly on the suspension installed on the vehicle and fully documented. Before this shock absorbers had to be removed for testing.

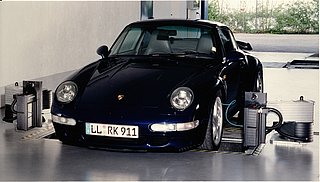

2000

First Voice-Controlled Wheel Aligner

Beissbarth launches the world’s first voice-controlled wheel aligner. The ML 5000 is not only a technological pioneer, but also a symbol of the digital transformation in workshop service. After the completion of the ML 5000, Beissbarth deliberately decided against developing further conventional measurement systems. Instead, the engineers invested in contactless wheel alignment – creating the vision for Touchless

From 2000

ADAS Calibration: Beginning with the VW Phaeton

For the VW Phaeton launch, Beissbarth developed the first radar sensor calibration solutions, based on precise alignment to the geometric driving axis – a principle still used in all Beissbarth ADAS solutions. Calibration tools for cameras, lidar sensors, and night vision systems followed in years after.

2005

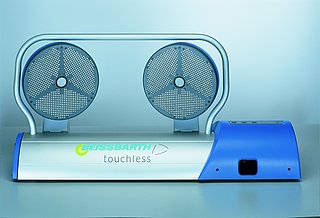

The Vision of Non-contact Wheel Alignment

Beissbarth launched the first contactless wheel aligner on the market. This innovation made physical targets and wheel clamps obsolete, as measurement was carried out optically through projections directly onto the rim. The name said it all: Touchless.

2014

Second-Generation of Touchless

With the second generation of Touchless, measurement was no longer performed on the rim but directly on the tire. This was made possible by an invisible laser beam, split into 16,000 individual points of light and projected onto the sidewall. The speed of Touchless 2 made a decisive difference, especially for high-volume tire chains and workshops. At the same time, many then-small and relatively unknown car manufacturers recognized the potential of Touchless 2 for their first production lines.

2016

Drive-over Tire Scanner

With Easy Tread, tread depth measurement became fully automated. What once took a long time and was purely manual could now be done quickly, precisely, and automatically while driving over the scanner. Instead of lasers, Beissbarth used a multi-color projection method that ensured robust results even with dirt and water entering the system. Unevenly worn tread patterns could also reveal potential alignment and tire pressure issues at an early stage—helping to unlock additional service potential.

2020

Q.Lign – Rethinking Wheel Alignment

With Q.Lign, Beissbarth set new standards in wheel alignment. Trolleys, PCs, cables, and printers became a thing of the past. Thanks to the new camera, electronics, and software platform, the measurement process was reduced to a minimum. Wheel alignment has never been this simple!